I know I have done posts (and YouTube) about decorating before, but its worth showing you how I went about decorating the sitting room for those who have just found me. I will also try to put in the smallest detail in case its something you haven't thought of.

|

| leaning at a jaunty angle |

I keep a piece of cardboard, which is three inches deep, to use to mark round the walls wherever I want a dado rail. This saves endless time trying to measure and mark in awkward spaces. Simply place it carefully against the wall, firmly planting the bottom edge on the floor and draw along the top edge, then move on.

|

| masked ready to paint |

I then put masking tape above the line as I am going to paint below the dado rail and paper above it in this room. Again, a couple of minutes putting on the tape saves many minutes of trying to follow the pencil line spot on.

Typing this is just occurred to me you could just paint the bottom of the wall first to the approx height of three inches and then mark up for the dado rail height and then paper to the pencil line - no need to tape - so even more time saved. Why didn't I think of that!! I probably would have been rubbish at guessing three inches and gone miles over or under, so its probably OK that I did this extra step.

We all find the materials we like and stick to them. I am OK about many paints - most are acceptable - but this Chalky emulsion from Craig and Rose is the ultimate in easy. It doesn't show brush marks, goes on easily, covers well in one coat (I choose to do two) and gives a nice slightly chalky finish. It would be very hard to beat.

Three walls painted in a couple of minutes, dries quickly allowing you to get the second coat on without waiting ages.

Handy tip: try to find the optimum moment to pull off masking tape. Too soon, while paint is very wet, and you risk marking other areas and smudging the edge, too dry and you risk peeling off some of the paint you want to stay behind. So try to find the moment where the paint is set up/soaked in but not bone dry.

This is a handy tool rather than handy tip. You can't get rulers in to measure some places in dolls house room and even a fabric dressmakers tape can be a bit thick and unforgiving in corners. These paper tapes from Ikea are great you can shove them into corners a mark up with a crease if you can't actually read the measurement in situ. I also just use strips of plain paper to make a template of the width of something and then transfer that to the object without any measuring units ever being involved. In this case I worked out my paper needed cutting into six-and-a-half inch wide strips.

Don't fit to the top edge of the wall if coving is going in because it is best to leave some area of wood for the wood to stick to rather than sticking it just on the paper.

Always keep the top edge of each of the sheets of paper as your top edge and don't trim along that edge, this way any pattern will always be running along the same 'line' right round the room.

Always begin papering on the back wall. If you have a chimney begin there. The first two pieces of paper you will cut will be the left and right side of the chimney breast.

All joins are in the corner unless you have a hugely long room or very short paper (!) Corners are always done in the same way so, depending on the piece of paper you are cutting you need to know if it will be the one which needs a little extra folded edge or whether it just needs straight cut. It works like this.

The back wall left and right edges need a small extra folded piece to wrap round on to the side walls and that piece of paper goes in first. The side walls will have a cut edge and will overlap the little wrapped around edge, so giving a lovely neat corner with no gaps any where.

This room worked this way.....

I began by cutting the left and right side of the chimney breast pieces of wallpaper. The sides of each of these pieces needed the small added edges. I put the paper on my board and use the lines as a guide making sure everything is square. I then rule down with a stylus to get a nice sharp crease. Your fingernail or handle of scissors will do - just a bit slower as more care is needed.

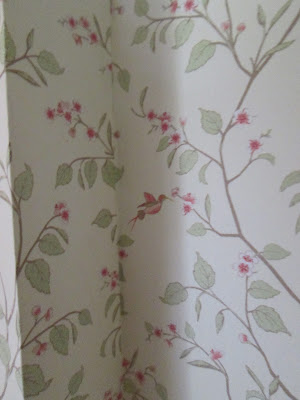

|

| click on photo for a better size |

Here is the right hand side 'panel' to go alongside the chimney breast piece. The chimney piece is simply done by holding the paper to the chimney breast and marking where the creases and cuts come; take the paper away and sharpen the creases and cut to size

Wallpaper paste! You choose. There is specific paste made for dolls houses, ordinary household wallpaper paste that you mix yourself, general all purpose PVA glue with a little water added and probably many more choices. I use the cheapest border adhesive I can find and it is perfect. I suspect it is just a thin PVA but it is silky, lump-free, easy to apply, tacks up at the right speed and does the job perfectly as far as I am concerned. My current one is called Diall from B & Q but I suspect any will do.

Here you see it is being applied with a spreader; in truth I use my fingers. I find that much faster and I get a better sense of the thickness of the glue and I can detect the slightest bit of debris, such as a fallen hair (white on white doesn't show!),

This is one occasion where I do practice what I preach. Keep the glue spreading area clean and wipe it between each piece of paper. You don't want glue on the front of the next piece of paper that you put there and you don't want any bits of anything on the glue side or you will end up with bumps in your walls.

I put glue on a piece, hang it, wipe over the pasting area with a surface wipe, dry with a soft cloth and then start on the next piece.

|

| again click to enlarge |

Here's the lovely join at the side of the chimney - it will never be seen but I know its good.

Many people cut papers into each corner with no overlap and many people have annoying gaps in their walls.

I unscrew the hinge and put it back in place when the paper is bone dry.

Decorating a room at this scale is much faster than one twelfth of real life time. It took just a few minutes to do this one all ready for floor and trims.

(19//05/16)